|

¡¡

Samsung

Semiconductors

My

life with Samsung was started with my first trip to Europe which was a

series of troubles from the start to the last minute as described in the

previous chapter. When I joined Samsung Semiconductors, 80% of products were

manufactured in Kiheung Memory Products Plant though the Samsung

Semiconductors was started with Boochun Non-memory Products Plant, which was

founded several years earlier by Dr. Kidong Kang as the Hankook

Semiconductors Co., who was my college classmate (1 year senior), one of

founder of Korean Amateur Radio League together with me, went to U.S.A.

right after the graduation of SNU, got PhD degree from University of

Minnesota, joined Motorola and worked many years there, returned to Korea to

establish Hankook Semiconductors, operated it a few years as the President

but failed the business which was taken over by Samsung.

Semiconductor manufacturing has 3 steps of process, once new product

is designed and passed QA Qualification Test for mass production. The first

step is "Wafer Fabrication" or "Wafer Fab" in short,

which is to print designed semiconductor patterns on 99.9999% pure (called

six nine) thin silicon plate with similar process as photography. Since the

distance between conductive aluminum lines are less than a micrometer

(1/1,000,000 meter) in 1960s but a nanometer (1/1000 of micrometer) these

days, it really requires extremely clean room and high technology, and this

Wafer Fab process is the most difficult process in semiconductor process.

(This is really the semiconductor manufacturing technology.)

The

second step is the "Assembly" operation, which was the operation

Fairchild Semikor or KMI have done. As each semiconductor chip is about the

size of finger nail or even smaller, depending on product, each silicon

plate called "Wafer" has hundreds of chips on it.

"Assemly" operation starts to separate this each chip and assemble

it into the package so that each unit will become a usable form on the

printed circuit board. This requires very clean room also and high

technology, but they are perhaps about 1/10 of "Wafer Fabrication"

technology.

The

last step is to "Test" (Called "Final Test") these

assembled final products to screen any defective product. Since there are

millions (billions today) of transistors in a chip, it takes quite a

technology, time and very expensive (more than a million dollar per tester)

computerized high speed tester to test them.

Since

a chip contains millions or billions of transistors in it and distance

between two conductive aluminum lines is less than a micro meter or a nano

meter these days (which is called nano technology), you can see them only

through the "Electron Microscope" and adjacent lines are so easy

to be shorted by any process error or dust of nano meter size. This is why

engineers or operators in Wafer Fab or Assembly rooms wear similar to space

suits and you have to wait at least 10 min. and wash your mouth before you

get in to the room, once you smoke cigrarettes. Otherwise, so small particle

from your smoking could easily short the line destroying the product.

Therefore,

the semiconductor manufacturing operation is always the "War against

Dust" and even when you shut down the operation for a vacation, the

airconditioner had to be continuously operated circulating air and maintaing

temperature constantly at 24-25 degrees Celsius. Once there is an accident,

it takes 3-4 days of air cleaning process before you restart the operation.

I

wonder whether this would be enough to scare you. However, this not really a

threat but the fact and semiconductor business is this much difficult high

technology business. Therefore, whenever I trained engineers, supervisors or

technicians, I said "We don't want any broad-minded people who are

usually respected by others in this society. We need detailed people who pay

so much attention to every detail and will never neglect any small detail,

though he/she would not be respected in this society." Because of this

kind of my life in semiconductor industry, probably I myself could not help

but becoming a very detailed guy unintentionally.

Any

way, when I saw the Kiheung Plant on the first day with Samsung, I was

surprised by so many things. First of all, it was the largest semiconductor

facility I have ever seen in my life with more than 10,000 people working.

When I toured each office, since new Quality Director joined the company,

every Dept. Managers came to me with their Section Managers and Sub-section

Managers and greeted me. While I was looking at the papers, I heard someone

shouting "Attention!!", just like a militqry camp, which really

made me scared. It was a Dept. Manager with their people to greet me and

salute military way.

I

started to smoke and asked them to smoke too (There was no No-Smoking

activity at that time and almost all adults smoked, but they were not

supposed to smoke in front of seniors by Confucianism.) to make them relaxed

with me and become closer friend rather than bureaucratic director. Now, it

was their turn to be surprised, as they have never seen any director asking

them to smoke together. It took several months to make them finally to smoke

with me together and to become much closer each other.

On

the other hand, as all 3 sons were already not living with us - Willy was in

San Luis Obispo attending Cal-Poly, Charlie had been a part time employee of

Hewlett Packard since 12th. Grade at high school and was

attending University of Santa Clara which cost was paid by Hewlett Packard

staying in dormitory of the university, and Johnny was in Hollywood, Los

Angeles attending UCLA. – we sold the house, moved to Seoul in Jan.

1987, lived in Hyundae Apartement provided by Samsung for a few years and

moved to Seocho Villa in 1990 which was built by Samsung for all directors

from U.S.A. as myself where we lived until we returned to U.S.A. in 1996.

Though

Boochun Plant of Samsung Semiconductors was started mucvh earlier, Kiheung

Plant for DRAM (Dynamic Random Access Memory) business was started only a

few years before I joined Samsung and operated as almost a separate

business. DRAM business was started by a great decision of Mr. Byung-Chul

Lee, the founder of Samsung, in spite of a great risk of the nature of DRAM

business and quite an amount of investment requirement.

Samsung

established SSI (Samsung Semiconductors Inc.) in Silicon Valley, hired many

experienced Korean PhD semiconductor expert engineers as Dr. Ilbok Lee to

collect the latest information of semiconductor industry and do some

research works there, brought some of them to Kiheung Plant as R&D

directors to lead design works of many local engineering college graduates

and PhD doctors majored electronics in Korea.

Any

way, Samsung was so different from much smaller companies I had worked and I

spent first few months just to understand the company and to think what to

do in the future.

Meantime,

I had found a few urgent jobs. The most urgent job was, while there were

many customer visits to Kiheung Plant, we didn't have data to present.

Rather than we didn't have it, we had too many data scattered here and there

but none summarized nor organized to present to customers. Therefore, QA

engineers had to create a presentation material working late until 11:00 PM

or 12:00 midnight, every time they were told customer would visit Kiheung

Plant. To make the situation worse, as the quality of the products were very

poor, they could not present the fact as

it was and had to adjust numbers

presenting somewhat false numbers to customers always. And the lie created

another lie next time and again and again and again endlessly.

I

felt strongly that this had to be stopped and changed to be honest to

customers and I had to brain wash Samsung people not only of QA but

everybody. I emphasized,

"The

greatest asset of the company is the "TRUST" of customers. No one

buys products from a company they can not trust. A lie will create bigger

lie next time and even

bigger lie at the following time endlessly, which will be discovered by the

customer sooner or later resulting

the end of the business with the customer. Unless we are going to close this

company within a few months or less than a year, but want to prosper

for a long time, we have to establish customer's TRUST first though we might

loose some business today."

As

this was my philosophy of sales learned and experienced at Fairchild Semikor

working as a Local Sales Manager, it was easy to explain them with actual

true stories I had experienced myself.

It

took few months to collect all available data from every engineer's drawers,

summarize them and prepare

a standard presentation material

with actual true data, which could be presented to any customer any time.

These data had been also always updated whenever new data were available

which had totally eliminated all the hard works of QA engineers to prepare

presentation materials for any customer visit including sudden visit without

any advanced notice. And this was what I had been emphasized – the

difference between hard workers and efficient workers.

The

next long term project was "Operation Instructions". This was

document describing what to do at the production lines – How the

equipment had to be set-up, the procedure how to do the job at what

sequence, how to handle materials etc. etc..

They

had "Operation Instructions" already. However, none of them was

detailed enough and so different from actual operation, as engineers

instructed to change the procedures so often verbally without revision of

document, whenever they had some kind of problem, just as the drawings in

Gold Star Co.,

Well,

the most important factor in mass production is the "Uniform

Quality". Every product produced is supposed to be exactly same. The

great benefit of automation is higher speed, lower cost and, most of all,

uniform quality as machine repeats same motion exactly same every time as

far as the machine is operating properly, which human can not do. Because

human motion can not help doing slightly different every time, the

"Operation Instructions" are the mean of minimizing these

different motions. This is the standard of operation in American or Japanese

companies, but it was not in Samsung. (Not Samsung only but practically all

Korean companies.) There is no way to produce "Uniform Quality"

without this "Standard Operation".

Therefore,

I prepared a 3 years plan of quality improvement called QIP (Quality

Innovation Project) and defined as -

First Year : Education and brain wash for "Uniform Quality" and

"Standard Operation".

Second Year : Rewrite all Operation Instructions to make it reliable.

Third Year : Make every worker in the line to follow them faithfully.

And

I established a new section called "Quality Innovation Section"

asking several additional people to Personal Dept..

We

started this new section with 5-6 people at first. I trained them "How

to write Operation Instructions" first and then "How to audit

lines as Line Auditors".

Because Samsung had been well known as an aggressive company, they said they

could do it in just a year. I said "It would be really great if we

could accomplish this project in just a year but changing human mind could

not be that easy. Let's see how long it would take."

Well,

3 years later, I think we could reach only 80% of my original target with

our best efforts. I believe even 80% was possible because I had lived with

"Standard Operation" for many years in American companies, had

strong mind it is the best way of mass production and was stubborn enough

not to give up regardless how hard it was. Especially in Samsung, they had a

great pride as the best managed company in Korea

and when I proposed and insisted

the standard operation, the Plant Manager said "It might be the way of

American company going down hill. Not the way Korean company needs."

(At that time, the Japanese economy was at the peak and the pro-Japan

company like Samsung had admired Japan very much, as they thought United

States was going to fall in pieces by Japanese

economic invasion.)

I

utilized the chances at the weekly "Quality Meeting" and monthly

"R&D Meeting", both managed by Plant Manager and my frequent

"Talkfests" with Dept. and Section Managers. (I called talkfests

with Dept. and Sec. Managers few times a week or several hundreds of times

while I was with Samsung just to brain wash them.)

At

Quality Meeting and R&D Meeting, I made mostly short comments to get

their attentions on problems and tried to change their way of thinking about

the quality and, at talkfests, I made long lectures, listened to their

opinions and responses and did my best to brain wash them about the

philosophy of quality. At this time, the word I used frequently was

"The Quality is not made by your finger tips but by your brains (though

the products are made by finger tips)."

There

was quite a strong reluctance at first, as they all had too strong pride of

Samsung. However, they were changed slowly and unnoticeably and it took

almost a year just to make them to think "Director Cho's word seems to

be right. I think we have to implement real Standard Operation."

There

was an unexpected advantage for me which was the "Respect Senior

always" tradion of strong Confucianism in Korean society. Since I was

the oldest among top management, only excluding Chairman Kang, all directors

were several years at least or more than 10 years mostly younger than me

including the president and they could not oppose me strongly face to face

and they had to pretend as if they were following me at least, even though

they didn't agree with me in their mind. I believe while they were

pretending, they had been slowly brain washed by me and became to agree with

me at last. On the other hand, R&D directors were very cooperative from

the first as they were mostly from

United States

and familiar to American system.

When

I joined Samsung, the President told me that there were daily 7 O'clock (PM)

meetings and it would be the easiest way to become familiar to Samsung

operation if I would attend all these daily meetings. What they were doing

was – they work until 6:00 PM, go to cafeteria for dinner and start 7

O'clock meetings of "Production-Sales Meeting" on Monday,

"Quality Meeting" on Tuesday, "Prodction Meeting" on

Wednesday etc. etc. for all six working days (Mon. – Sat.) which

lasted until 9:00 PM usually or even later some days. (I found no one knew

or paid attention acturally about their official working hours except they

knew they had to start to

work at 8:00AM)

As

a newcomer, I had no choice but to follow the suggestion of the President

and attended all these meetings for a few weeks. However, it really made me

too tired working so long hours every day which I had never done in my whole

life. Therefore, I skipped one meeting and another one by one and attended

only Tuesday's Quality Meeting in little

more than a month.

In

addition, they worked not only 6 days a week of normal working days but

Sunday also without any holiday at all during whole year. Therefore, I

declared form the start that "I had worked only 5 days a week in American

companies but will work 6

days a week. However, I am too old to work 7 days a week and have to take a

rest on Sunday at least." I never worked on Sunday in Samsung.

In

the evening also, since every director/manager went home at 9:00 PM at

earliest, I couldn't leave my office at 5:00 PM sharp but left at 6:00 PM

when they all went to cafeteria for dinner. I didn't know whether they were

generous to old man due to Confucianism (though I was only early 50s), they

didn't have too much interest on Quality or they just concluded

"Director Cho" was that kind of person, I had heard no complaint

from Samsung Group head office while I was told all directors' attendances

were reported to the "Secretaries Office" of Samsung headquarters.

Well, I had no interest on promotion in Samsung any way and I didn't care

how they thought of me.

While

I was trying to convert the mind of people, I started to visit major

customers in

United States

and

Europe

. When I started the customer visits, wherever I went, there were plenty of

quality complaints.

But

all I could do was to explain my 3 years plan (QIP) and ask them to give me

more times to improve the quality. However, customers were still complaining

as "We have immediate serious problems. How can we wait for 2-3

years?" I could understand their situation but had no answer. I had to

just apologize and to say "You have many years of experience but we are

just two three years old baby." I tried just to focus on immediate

problem only as much as possible and discuss what to do next for the

problem. It was extremely hard time for Samsung and for me too.

As my customer visit trips to

U.S.

and

Europe

became more and more frequent, it was not easy to fly for more than 10 hours

frequently though Samsung gave business class tickets to directors. One day,

after the directors' meeting, I asked Director of Administration, who was

very friendly to me, whether I could take first class considering my

frequent long flights, which was allowed only to Presidents or VPs. He

replyed "OK" so easily and I took first class always thereafter.

In

spite of poor quality, customers didn't have much choice but to buy DRAM

from Samsung as the supply was tight. As the company paid attention to the

Production and R&D for more and new products, all available fund was

allocated to them mostly and QA didn't get much attention and QA testing

equipment was not enough to function properly. I included additional

equipment and man power into QIP and, by the strong support of the Director

of Administration who was always the most powerful position in Samsung, we

could gradually improve our testing capability. (Since QA still spent only

very small portion of total company budget and I don't think it was a big

deal for the Director of Administration any way.)

As

QA got more and more equipment and engineers were more and more experienced

noticeably, QA detected and picked up more and more defects and problems.

These data was summarized and presented regularly to the management at

various meetings. Now, R&D had to be far more careful designing new

products.

One

day, at a R&D Meeting, QA reported some minor problem and asked R&D

to fix the problem first before we start the mass production. Since it was

an urgent product for business, not only R&D but Sales also suggested to

start the production first. I said "Well, since it is not a major

problem, I can let you start the production. However, because I was

complained same problem once from IBM, I can not allow you to ship them to

IBM at least." I knew they need it for IBM. Finally, R&D accepted

my suggestion to fix the problem first before they transfer the product to

the Production, and Sales also expressed their appreciation to me later,

though they really wanted to ship the product as soon as possible at first.

Meantime,

I trained members of Quality Innovation Section for Standard Operation, how

to prepare Operation Instructions and how to audit lines, myself for a few

months and sent to the production lines to audit them. The result was just

as expected. They found only 5-10% of the Operation Instructions were

followed. When we sent out this audit result data to the management and

lines, they didn't want to believe it and we received various kind of

complaints

from them. However, as the data was accumulated and they were explained

about the data, gradually they had no choice but to believe the data and

they voluntarily started to rewrite all Operation Instructions.

I

made a rule

that all newly rewritten Operation Instruction had to be reviewed

and approved by Line QC and QA

before to use them. Since they had never written perfect Operation

Instructions, most of rewritten Operation Instructions were not good enough

either for quite a long time and they had to be rewritten again and again

many times

until they were finally approved by QC and QA. It took more than a year,

just to rewrite most of Operation Instructions making them barely usable. On

the other hand, due to better Operation Instructions and more attention of

everyone, the "Obedience Rate" of the Operation Instructions had

been steadly improved upto about 40% from 5-10% initially but almost stopped

there because of still poor quality of Operation Instructions and limit of

attentions of line people including, operators, supervisors, technicians,

mechanics and engineers.

To

get their stronger attention, we distributed the audit data throughout whole

plant every week, made each line to compete each other awarding best lines

and talked a lot about the result of audit during regular talkfests with

Dept. and Section Managers constantly to brain wash them. By endless effort

of everyone in the plant and my stubborn personality, when I left Samsung

Semiconductors, the Obedience Rate was improved to almost 80% though my

target was 90%.

As

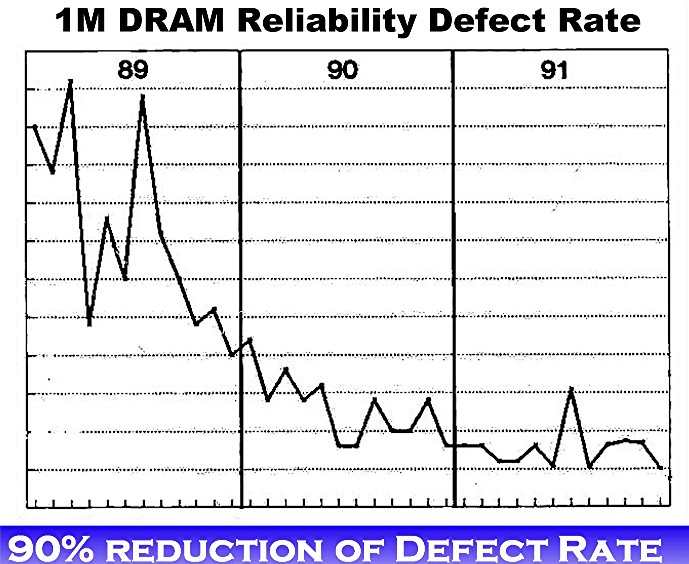

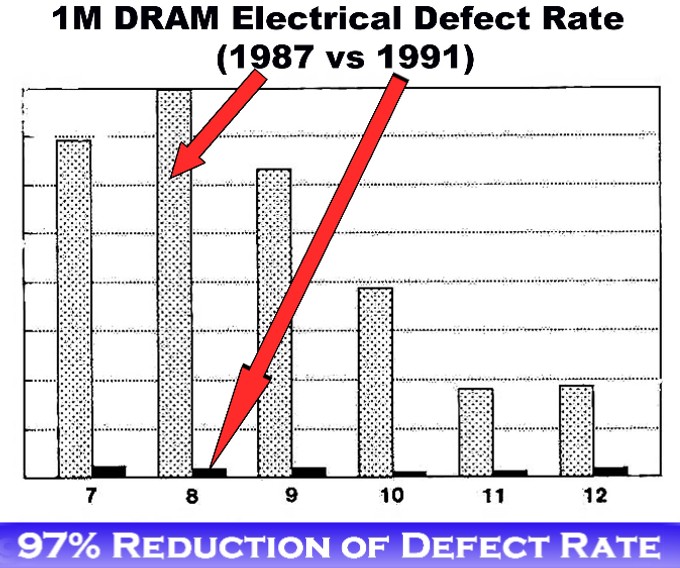

the efforts of QIP progressed, atmosphere of Samsung Semiconductors had

changed slowly to pay more and more attention to quality and quality data

started to show improvement from a year later since we started QIP. After 3

years of QIP implementation, Samsung quality is recognized by our customers

as almost same as Japanese DRAMs and, after 4 years, we were told from many

of our top customers that our quality is even better than Japanese quality

finally and the BEST in the WORLD !! From this time, my customer visits were

not painful any more but rather pleasure for me. There were many interesting

events at around this time.

One

day, Hewlett Packard purchasing people visited Kiheung Plant with their

engineers and told us they had about 1.5 million dollars worth of order to

release but could not release because of the quality of Samsung DRAM. Sales

people tried to convince them but

they were too reluctant.

I

met them at the conference room and made a presentation about our past,

present and future quality trend. I said "In my understanding, I am

confident our quality is at least same as the Japanese or even better than

them according to our data as well as our top customers' comments. The only

problem for me is we have had no chance to prove it to Hewlett Packard yet.

I don't think I can ask you to release the order as far as you are not

confident. All I can say is how much you can trust me."

They

asked a break, went next room for about 15 minutes, came back and said

"Since you have never lied to us, we trust you. We will release the

order based on your statement." I could prove to all Samsung people how

important and valuable the mutual trust would be each other for mutual

business, as I had always emphasized and prohibited to generate any false

data any more.

Another

event was NCR case. One time, semiconductor business was booming and DRAM

price shot up by 20-30% in a few months as supply was short. Samsung raised

price as well not to miss this chance but raised price for the volume

already booked before price increase. This was not the general practice of

business and NCR was really mad and declared to stop the business with

Samsung any more. NCR even notified to Samsung not to send any one to their

office any more.

When

I went to SSI in Silicon Valley, I heard this story. I decided to try my way

and called NCR director myself whom I have met a few times.

I

said "In my understanding too, Samsung did lousy job ignoring general

business practice just because they are not experienced to international

business too much yet, though it have been usual within Korea. I really feel

guilty to NCR and would like to visit your office just to apologize and

explain the situation little bit. Under the circumstances, I have no

intention to ask you to buy our product. This will be the visit just for

apology only and will buy a lunch for people there as a gesture of apology."

Well,

since Sr. Director of Samsung was proposing a visit of apology only, he said

OK and asked me to come alone without any other salesman.

I

went to a small town of Wichita,

Kansas

alone where NCR had purchasing office with product qualification testing

facility. They might perhaps be curious or had nothing much to do. There

were about 30-40 people in conference room to see this crazy Samsung Sr.

Director.

I

didn't say much but "This had happened because of the lack of

experience of Samsung who is still only a few years old baby. All I came

here to say is nothing but we are very sorry. I can not ask you to buy our

product as I can understand your feeling about Samsung. All I would like to

do is to show you where our product quality is and how it is going to be

improved in the future just because my job is Quality Director in Samsung. I

would like to visit here every quarter and report the progress which might

interest you for some day in future. Would you allow me to do quarterly

visit just for quality presentation only?"

I

made very brief quality presentation and went for lunch with a few staff

members. It seemed the NCR Director was little relaxed and said "We

would like to buy Samsung products but the quality is still poor and

Samsung's action against general business practice really made us mad."

And he said OK to visit them quarterly.

After

this event, I visited NCR every quarter for more than a year but never asked

them to buy our products. About a year and an half later, the Director said

"Your persitancy won. We now know where your product quality is

according to your presentation. We just need to perform few tests to confirm

whether your data is true or not. Send us some samples to test."

Then on, NCR had been very friendly to us. They did very few simple tests

only of our products and qualified us to their purchasing. Now, NCR business

was reopen again after one and a half years of my persistent effort.

We

had few more occasions of this kind of episode and a Sales Dept. Manager

said "About half of DRAM sales was made by Director Cho, not by

salesmen. Thank you very much." Well, I knew there was some

exaggeration but it was not a totally groundless statement, and I felt very

good.

As

Samsung DRAM quality is well recognized as the best in the world among

American major customers, I proposed to Marketing to get in to Japanese

Market. As there were few famous DRAM makers such as Toshiba, Hitachi,

Fujitsu, etc. in Japan, they had no reason to buy Korean DRAM. However,

United States put the pressure on Japan and forced them to sign U.S.A.-Japan

Semiconductor Treaty, which defined Japan to buy 20% of their semiconductor

demand from outside of Japan. Of course, this was to sell U.S.

semiconductors to Japan. However, why don't we take advantage of this treaty

and sell our product to Japan? If they had to buy 20% of total semiconductor

usage out of

Japan

, DRAM must

be the easiest product to satisfy

20% requirement as it was a single product requiring largest volume for all

computers.

However,

Korea,

Samsung and Hyundae,

was the only country producing DRAM other than

U.S.

and

Japan

and Hyundae wouldn't dare to penetrate to quality sensitive Japan

because of their very poor quality, which left only Samsung to try. My idea

was to take advantage of this best chance as we wouldn't even

need to sell at

cheaper price

either.

However,

because

Japanese product quality was very

high on all products, they had been so quality sensitive and they had to buy

products they didn't want to buy from foreign country, it had to be a tough

challenge and the Sales hesitated to get in at first. My another intention

was, though many world top customers have approved our DRAM as the best

quality product in the world, I wanted to challenge these extremely quality

sentive Japanese companies who would find lot more defects than American

companies. As they find more defects, it would work as stronger pressure to

our R&D and Production people, especially in Samsung which had been very

pro-Japan company,

and it would force our QA engineers to work harder and learn more, which

should result even better quality. Any way, since there was no sale in

Japan

at all, there was nothing to loose other than small amount of sales

expenses,

Finally,

the Sales agreed and we sent samples with our testing data to Samsung Tokyo

office to distribute them to top Japanese computer makers who were also DRAM

makers. And the result was – "No way. There are too many

problems, none of them are interested and it is too early to penetrate

Japanese market.

Well, it was expected from the first already. I started to visit Japan

frequently. I visited all Japanese potential customers myself and made

presentations of our DRAM quality.

Because

of Japanese occupation of Korea, I learned Japanese at elementary school

(Actually, we were allowed to speak Japanese only. Speaking Korean was

prohibited.) and I talked a lot with Japanese radio hams over the ham radio

communications every day at home after ham radio was licensed in Korea when

I was in College and thereafter until we moved to U.S.A. in 1973, my

Japanese is still far better than my English. It is much easier language for

me than English to speak and listen, almost same as Korean. Therefore, I

could make all presentations and conversations with them in Japanese without

any difficulty, almost same as a Japanese, which itself made them to be

amazed.

However,

the response was quite negative for a while. Especially Toshiba, the largest

DRAM maker at the time, was the toughest and complained me that they could

not accept one defect out of 1,000 samles in our Reliability Test data. What

they were saying was there should be "Zero

Defect".

I

defended as "I have never heard any product in the world have ever

achieved Zero Defect though it is the final goal and dream of our Quality

people always. One defect out of 1,000 samoles means it could be zero if we

were little luckier during sampling or could be two defects if we were

little more unfortunate. I think it was nothing more than the matter of luck

while we were sampling. We just wanted to be honest and showed one defect as

we found dring the test. If you would like, I could submit you new data changing

to zero defect. As it is within

the tolerance of luck, I wouldn't feel too guilty even I change the data as

you please."

Well,

they couldn't argue any more and Toshiba became the first Japanese customer

to buy our DRAM after more than a

half year of intensive testing of samples and other customers followed one

by one. It took more than a year until all Japanese customers approved our

DRAM finally

One

day, we were reported that our product had a quality problem in Toshiba. I

immediately flew to Japan and visited Toshiba. It was not a functional

defect but a simple cosmetic defect of marking problem. The Samsung logo,

product name and manufacturing date printed on top of the product was not

clear enough but tarnish,

making it little difficult to read. I said "This is not normal but they

are still legible." The Toshiba guy said "Ya, it is true. However,

if you are going to buy a girl paying same money, are you going to sleep

with a beautiful girl? or a ugly girl?" We laughed so much and I

promised them to replace the products.

During

this time, I traveled to Japan almost every month. As Japan was just less

than 2 hours of flight, it was much easier to travel and to communicate too.

However, they were all so tough and more than 50% of customer problem reported

to QA was from Japan while we

were selling less than 10% of total sale to Japan. Therefore, QA spent lot

more than 50% of customer service time for Japanese customers to analize the

defect samples and prepare reports and action plan for them. On the other

hand, this also helped a lot for our QA engineers to learn a lot, to develop

their Failure Analysis technology and improve our quality. And it

contributed a lot also working as a great pressure to R&D and Production

just as I had originally expected.

It

had been the story of Kiheung Plant Memory Products. However, I worked 2

days a week in Boochun Plant where I had another office. Not only the volume

of Boochun Plant was far less than Kiheung Plant, they were mostly shipped

to domestic customers who usually did not complain about Samsung products.

There

were separate QA organization and Quality Innovation Section with several

auditors who did same job as Kiheung Plant to implement Standard Operation through

QIP there too. As Boochun Plant

was also producing simple transistors and many cheap non-memory

semiconductors which had been all discontinued in Japan, Boochun had quite a

business with Japanese electronics companies.

One

day, We were informed from Tokyo office that Boochun transistors, shipped to

Sony of Japan and reshipped to Sony U.S.A. plant, caused a problem in U.S.A.

plant. I was going to visit Tokyo any way very soon and flew to Tokyo

immediately on very next day visiting Sony Purchasing office on the day. I

just listened to the complaint, received defective samples and returned

without any comment other than to say sorry.

The

problem was we had no idea to pin point what had caused the problem in

spite of our best efforts doing

all kind of failure analysis as far as we know. It looked like it was just a

simple operator mistake which

would never be accepted by Sony as we had to explain them how we would

totally eliminate the cause permanently. Just retraining of operators would

never work with Sony as a corrective action.

We

did all we can do for several days but there was no solution. Well, we had

to create a story somehow and wrote a failure analysis as "We found one

machine caused this problem and we have overhauled the machine. Therefore

there will be no more same kind of problem in the future."

I

submitted this failure analysis report to Sony visiting them again in less

than a week. However, Sony Quality Section Manager smiled and said "We

can not agree it. We think problem is such and such¡¦. Would you check

again from our view point?"

I

came back to Boochun and investigated from Sony's view point. However, we

found nothing new.

It was not a problem occurring frequently and not a serious problem either.

Still, it looked like no more than a simple operator error. Well, what could

we do? We had no choice but to write another fictional story again from the

view point of Sony this time.

I

visited Sony in less than a week again. A Sony Quality Section Manager

looked at our Failure

Analysis

Report

and smiled again, and said "We can not agree on this report either.

However, I am really impressed on Samsung's effort to care customer this

much. I have never seen any vender that Sr. Director visits us 3 times in

less than 2 weeks himself and try to solve a problem. Since this is not such

a serious problem, let's forget it this time. As I am impressed so much, we

will buy a lunch for you."

Usually,

Sony was well known as the toughest company on quality problems. However,

afther this incident, Sony had been so friendly to us, never complained us

and always asked us failure analysis only without asking corrective asctions

sending failure samples. This was another event to show how the sincerity to

customer is important for the business always. Thereafter, I just visited

Sony almost every time I traveled to Tokyo and had lunches with them just as

a friend regardless we had a problem or not and this was one example that

"A problem turned to a friendship."

There

was another episode with Japan. There was a quality problem with Kyushu

Matsushita who sent samples for our failure analysis. As Boochun QA couldn't

find right cause of the problem, they just delayed, delayed and delayed the

response for more than a year which was not reported to me as they didn't

think it was a serious problem. Now, the engineer of Kyushu Matsushita who

waited, waited and waited the response of Samsung was mad finally and told

Samsung Tokyo office that they will discontinue business with Samsung and

asked to stop all shipment immediately.

Well,

it became a serious problem now and Samsung Tokyo called me asking what to

do. I called Boochun QA engineer and learned the history of this incident.

It looked like it was 100% our fault not responding for more than a year and

there could not be any excuse. I immediately flew to Kyushu and visited the

customer with QA Dept. Manager and Samsung Tokyo office salesman.

During

the visit, I didn't ask any excuse but just said "This is totally our

fault and I can not find any excuse. It is fundamently my fault not

supervising my people properly. I just came here soly to apologize, not to

ask excuse."

The young engineer of Kyushu Matsushita was so mad and complained for an

hour, while I repeated nothing but "Sumimasen (Sorry)" over and

over. After more than an hour of scolding, we left the customer without any

solution or agreement. When we came out of the meeting room, the Sales

Section Manager of Tokyo office said "It was amazing how you old

Samsung Sr. Director could possibly say nothing but Sumimasen only all the

way to such a young engineer. I don't think myself much younger than you

could do it." I said "Well. It was totally our fault. What can I

say? If I defended ourselves, he will be more and more mad making the

situation much worse. Let's wait and see. I believe the problem is solved

with this visit." His face showed he was amazed again.

Any

way, the problem was not solved on the day. But very soon, we could start

the shipment again to Kyushu Matsushita (There was no place to buy that

product, as no one but Samsung was producing it any way.) and the engineer

was not mad any more. I believe he felt very good after an hour of scolding

to an old Samsung Sr. Director and, first of all, my sincerity and honesty

have worked again.

There

were many this kinds of event which I will finish here. It was my great fun

to solve this kind of difficult problems and the Samsung Sales asked my help

whenver/wherever there were serious problems, which made me very popular

among worldwide sales people,

though I had to travel a

lot all over the world.

In 1990, I was

out of town traveling

foreign countries for 2/3 of the days. It was the time our quality was just

started to be recognized by world major customers but not fully proven to

them yet, which made my job still hard enough.

I

talked about the fun part of the work. Of course, there was a hard part as

well as fund part. I didn't like the bureaucracy and formalism of Samsung

and told Jane "I will quit Samsung within a year" so many times

which she didn't believe any more, as I repeated it for years and years. It

was almost a miracle for myself how I could survive for more than 10 years

in Samsung but I could do

somhow, because I had a lot of

fun solving this kind of difficult problems, making progress of quality

slowly but steadly, which no one else could do, and enjoyed a lot of special

benefits of Samsung for directors.

One

of the key fact I could achieve this success was the president Kwang-Ho Kim,

my boss, had never intervene my job but let me do my way always. I had never

heard his praise but scolding neither. I didn't know whether he had totally

trusted me, he was extremely patient for my work or he was not much

interested in quality any way. At any rate, he had left me to work my way

and just supported me at directors' meetings making a few comments in favor

of me which was very helpful for me. And that was how I could do my job as I

wanted always with fun and how I could accomplish all this success in

Samsung.

One

of the great benefits of Samsung directors, which was one of the major

reason making me to stay in Samsung for more than 10 years, was unlimited

expenses. Regardless it was a personal use or official expense, all I had

to do was to give receipts

to my secretary even without any explanation. No question was asked.

Therefore I had

entertained not only customers, but also my family, relatives and even

friends very frequently at best restaurants always, though, still, I believe

I spent far less than other directors who liked

to drink while

I didn't.

I always traveled with first class air tickets, stayed at the best hotels,

was entertained at the best restaurants by Samsung oversea sales office

managers wherever I went,

and played golf worldwide whenever time permits. Especially, when I traveled

to U. S. A., I came to San Franciso first always, went best restaurants in

Bay Area with not only our children but also many friends. And this was one

of the reason I cound't quit Samsung earlier.

Just

because of Korean customs perhaps, Samsung directors never took wives when

they went official trips. Even though they took wives together, additional

cost for the company would be meal cost for wives only which would be

minimal. But there was no brave enough director to break this customary

practice.

Well,

I was not interested

to be promoted in Samsung any way. I was already well recognized as a crazy

guy company wide, not working on Sunday, going home early etc.. Why not to

break this practice? In Septmber, 1990, when I travel to Europe to visit few

customers, I took Jane together who had never been to Europe. I got a free

first class KAL ticket for her using my KAL mileage already accumulated a

lot as I always traveled first class. I planned to go to London first alone,

spend about a week visiting customers there, fly to Paris where I would meet

Jane arriving from Korea, visit few more customers there while Jane look

around Paris and start about 2 weeks of Europe sightseeing tour together

thereafter.

In

Paris, Sang-Soo, the son of my eldest sister, lived there as a student

working as a tour guide too as a side job and Jane could enjoy Paris tours

guided by almost professional Sang-Soo while I was visiting customers. After

my official work in Paris, we flew to Geneva, Switzerland, where our QA

Section Manager Yoon-Shik Kim was waiting for us at the

airport with his car. Y. S. Kim

was stationed in Samsung Frankfurt office, dispatched by Kiheung QA to do

customer service more efficiently in Europe for a few years, drove his car

(company car) from Frankfurt to Geneva airport to meet us and traveled with

us together for about a week driving around for

us.

We

drove beautiful Swiss roads to Interlaken through Zurich, where we stayed

one night and took a train to Jungfrau of Alps. From there, we drove to

Heidelberg, Germany, not too far from Frankfurt, looked around this famouse

city which was a part of famous movie

we saw when we were college

students. Then, we drove to Frankfurt where we visited Lorelei, not too far

from Franfurt, and flew to London together with Y. S. Kim, had a great

sightseeing of London area, played a round of golf and flew to Milan, Italy.

Meantime, Y. S. Kim always took care of us all the way. In Milan, local

Italian salesman guided us driving around Milan, Venice, Florence, Rome,

Pompei, Napoli etc. with his car for another week.

This

fantastic and luxury trip was all paid by Samsung except very minimal pocket

expenses. Everywhere we go, Samsung sales office managers entertained us

very well. They were so surprised that I took Jane together for the trip and

envious for the courage. No one showed any negative expression at all and I

really appreciated for their great entertainments.

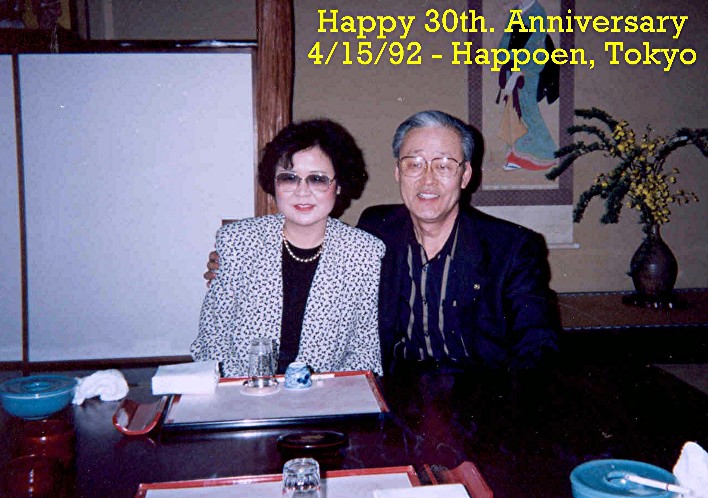

Another

trip was in April, 1992. April 15, 1992 was our 30th. Aniversary

and Jane had stopped by Tokyo few times on the way but never really saw

Japan. I planned to take Jane to Japan and spend the Anniversay day in

Tokyo, as I had a customer visit trip plan. (I actually adjusted the trip

date.)

After

the customer visits for a day or two, we had a Japanese traditional dinner

at a Japanese restaurant called "Happoen" on 4/15 which was well

known as the top class Japanese style restaurant. Next day, we visited

famous Hakone and Kamakura and went to Kyoto on the following day. I had

arranged the first class seats of bullet train from Tokyo to Kyoto as it was

our anniversary trip.

When

I go to Japan, I usually stay in western hotels but prefer to stay in

Japanese inn in Kyoto only

as it is really a traditional

city of Japan. It was the time of cherry blossom very fortunately and Kyoto

had a Cherry Blossom Festival decorating whole city with cherry blossoms

which is their national flower. I took a Japanese inn very next of Maruyama

Park where the cherry blossom was really gorgeous.

We

stayed in Kyoto for a few days visiting Osaka too and enjoying old tradition

of Japanese culture including wonderful real Japanese sukiyaki. In Japan

too, as he got a lot of help of me, the Samsung Tokyo office manager

entertained us very well with another QA Sec. Manager stationed in Tokyo who

took care of us all the way and this was another luxury trip in free of

charge, as I got a first class free ticket for Jane from KAL again and all

expenses were charged to Samsung as a customer visit trip expenses.

I

worked for Samsung Semiconductors this way for about five and a half years.

When I returned from trip to Japan in 1992, I was called by Chairman Jin-Koo

Kang, who was my few years senior at Engineering College of Seoul National

University. He worked in broadcasting field long time, joined Samsung when

Samsung started the first commercial TV bradcsting station of

"Dong-Yang TV" as the chief engineer and became a Chairman of

Samsung Electronic Group later. I met him several times when I worked in

Radio Seoul and he in

Dong-Yang TV, both Samsung subsidiaries, but met a lot more frequently at

directors' meetings after I joined the Samsung Semiconductors. I heard he

praised Sr. Director Cho frequently

at special lectures of Samsung Training Center but never parised me face to

face, which was usual and very customery in Korean companies.

Any

way, I went to his office at Samsung head office in Seoul and was proposed

to work at Home Appliance Division of Samsung Electronics, as Semiconductors

seemed to have good enough quality to compete in the world market but home

appliances are still too much behind of Japan. He wanted me to go to Suwon

Plant and improve all home appliance products quality to the level of

Japanse companies.

I

didn't accept the proposal at first as my specialty is in the semiconductor

operation where I worked almost whole my life but know nothing about home

appliances. However, he insisted as the home appliances quality had too many

problems and Samsung had been facing too much difficulties competing with

Japanese products not only in the world market but also in domestic market

too, requiring very innovative change throughout the whole operations in Suwon Plant.

Since

he was insisting so much to work in Suwon Plant, I had nothing to loose. I

said "I worked for the Semiconductors for five and a half years but my

salary had never been raised, as they say it is based on the initial

contract. As the result, it was actually lowered by absolute value because

of annual inflation. If you insist to work for Suwon Plant, don't you think

my salary had to be readjusted for annual inflation at least at this chance

to start new job? In addition, Suwon Plant is 3-4 times larger organization

than Semiconductors which will be much harder to manage and I think it is

fair to raise my salary by 30% at least."

I

myself knew it would be ridiculous request as I believed Samsung never

raised any salary by 30% at once. However, I was surprised when he instantly

accepted my proposal. I could realize he valued me very highly but could not

praise me face to face because of Korean tradition. Well, if the Chairman is

backing me, what should I worry about? I finally accepted his proposal, left

the Semiconductors at the end of May of 1992 after five and a half years and

moved to the Home Appliances Division of Samsung Electronics. By that time,

Samsung Semiconductors was a another division (Semiconductors Division) of

Samsung Electronics Co. – SEC.

¡¡

|